Production efficiency is defined as the effectiveness with which resources such as raw materials, materials, labor, machinery, equipment, and energy are used during production. You can boost productivity by separating these heads into three different mattress producing branches.

1. Efficient Raw Material Utilization

Using raw materials efficiently also entails making use of the “money” aspect, which is the most essential factor in increasing efficiency. Keeping raw material unit pricing up to date is a crucial aspect that increases efficiency, in addition to making the suitable raw material requirements and generating the most appropriate production plan.

2. Increasing Employee Productivity

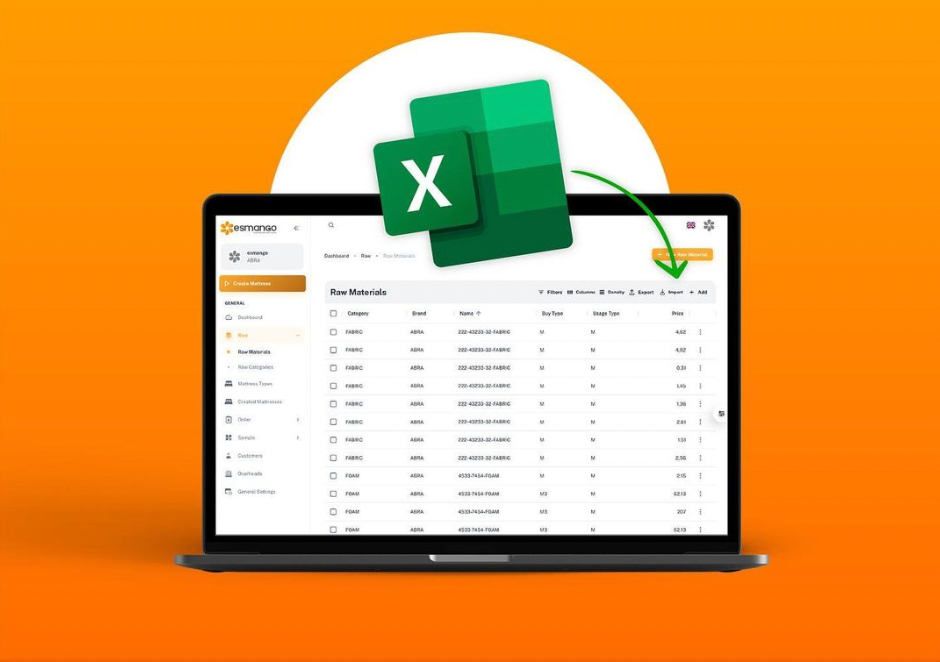

Minimizing manpower costs allows to increase employee productivity. Taking use of emerging technologies is the best approach to reduce labor expenses while increasing employee productivity. Making raw material requirements, for example, which is a lengthy and difficult procedure, using technological advancements rather than an excel spreadsheet will be the greatest benefit that allows you to boost staff productivity.

3. Effective Time Management

Time is one of the most critical aspects that should be used efficiently, beginning with the prescription stage and continuing through the packaging and delivery stages. Integrating technology advancements into your working system is the most effective approach to use time productively and save time. Collecting the raw ingredients you require in a single list, for example, and employing a system that performs all measurement calculations automatically saves you a lot of time.

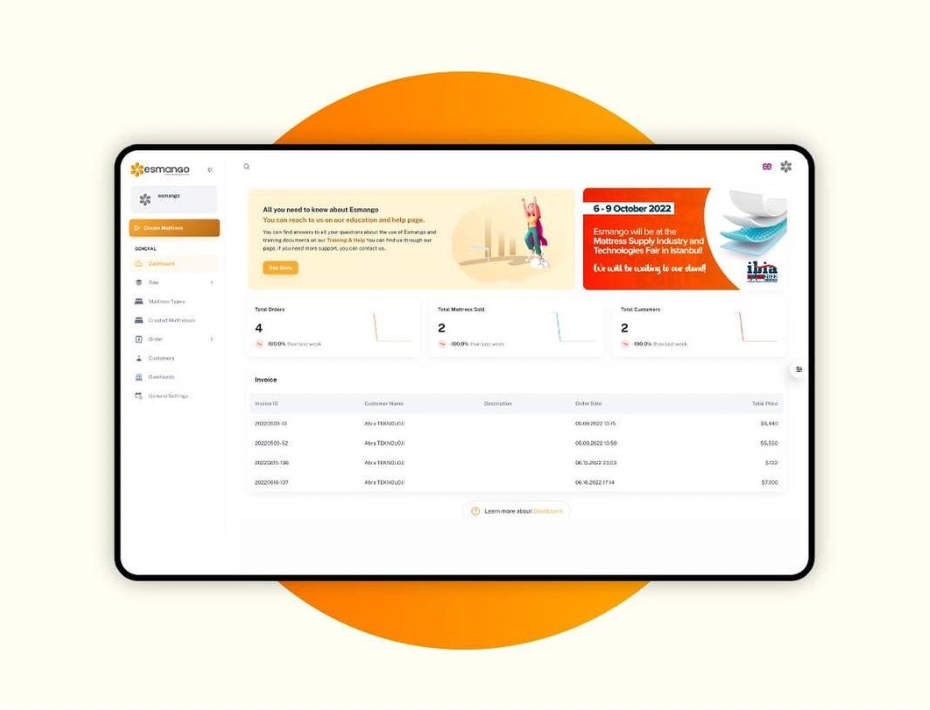

With the fast, simple, and cloud-based Esmango Quick, you can manage and control all of these processes that boost productivity in mattress production.

Follow us to stay up to date on technology advances and industry trends.